3D Printing

3D Printing

3D Printing

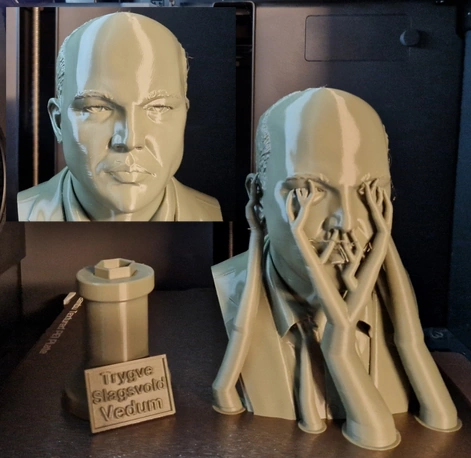

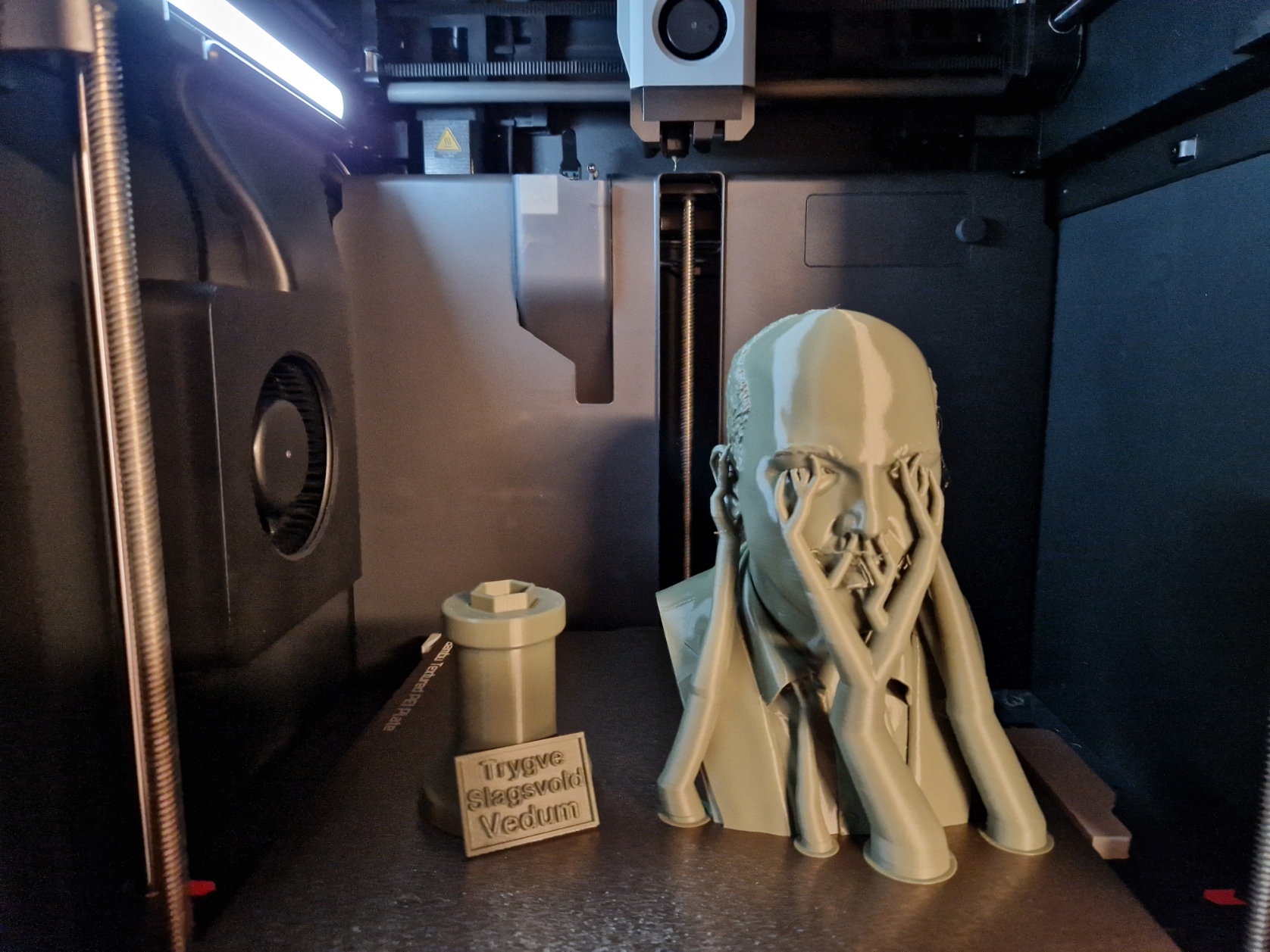

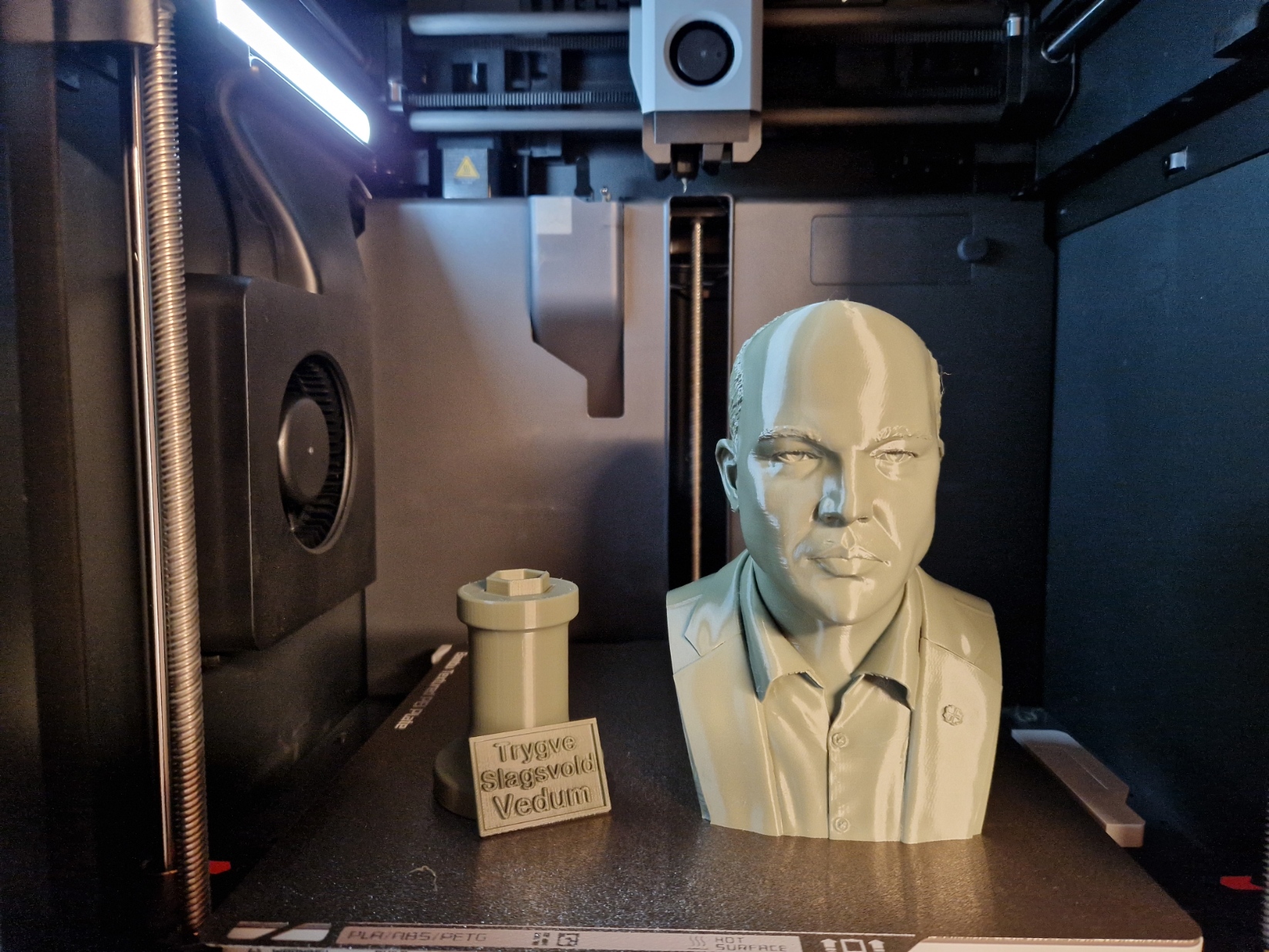

All our products are 3d-printed in our little factory.

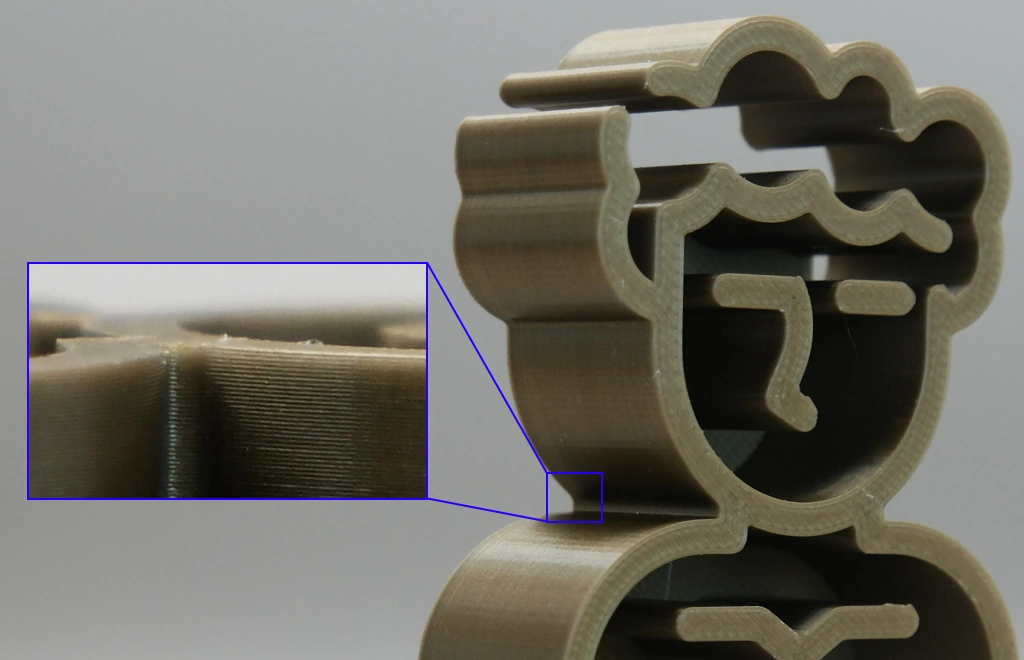

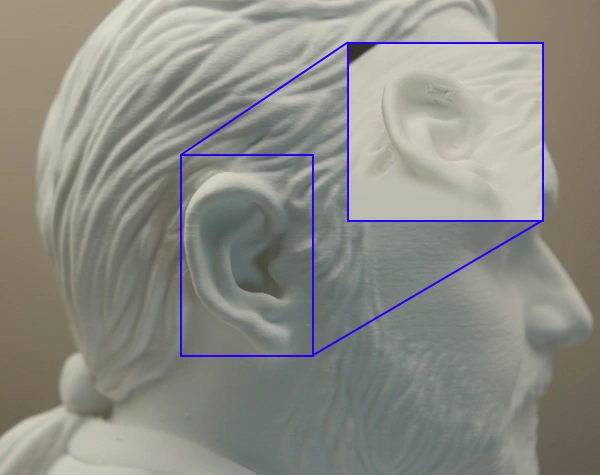

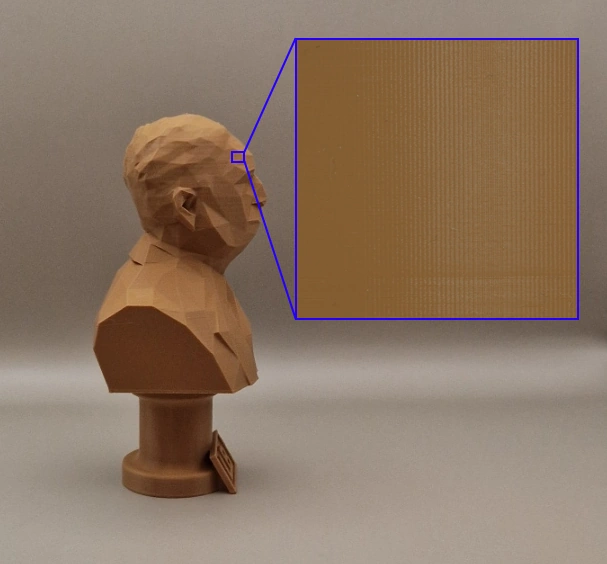

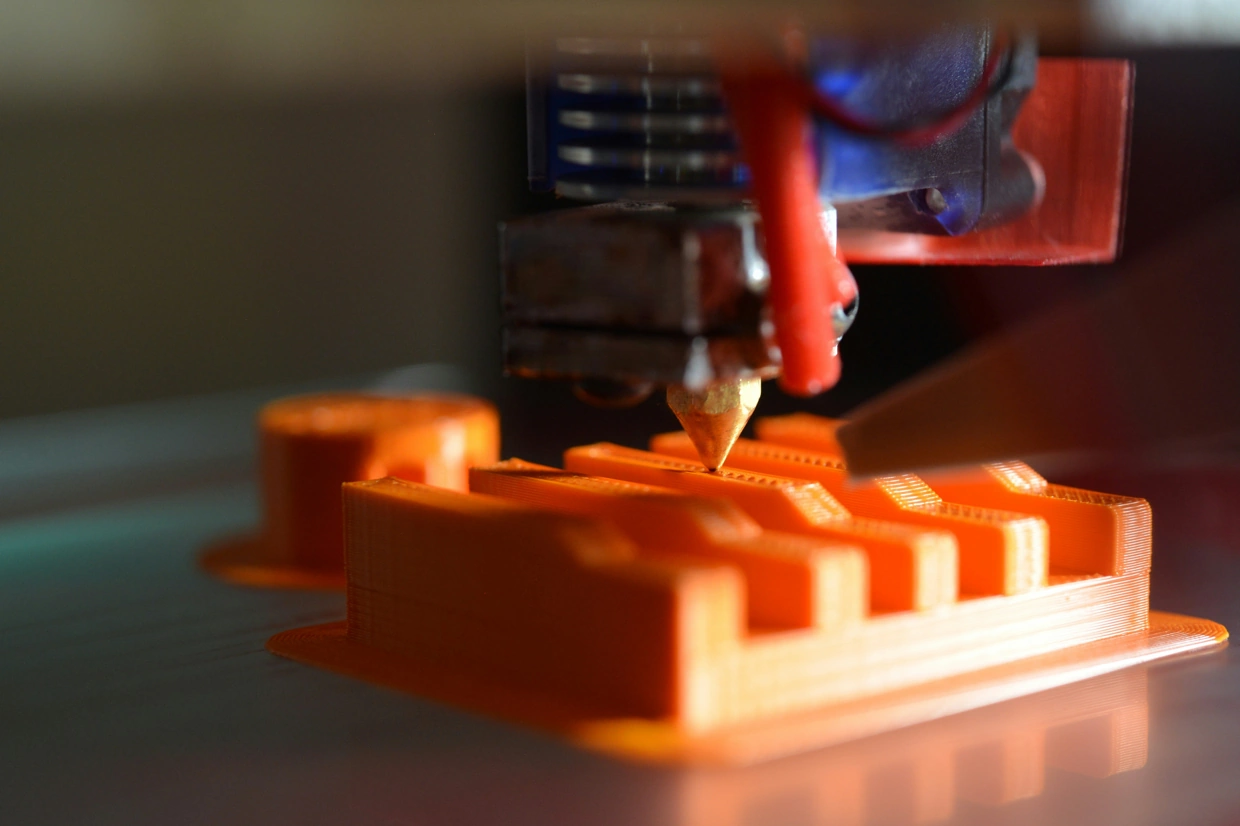

3d-printed objects are made by laying down successive layers of material (plastic) using a precision nozzle that moves and deposits melted material based on instructions from a computer. We typically print in 0.12 mm thick layers so a 24 cm bust has a total of 2000 layers that must be printed. This makes 3d-printing time-consuming. Our largest busts can take well over 24 hours to complete.